.jpg)

Quality and low costs are decisive for all production processes. Solar cell manufacturers also attempt to maximize the number of cells with high efficiencies and good visual characteristics so that as many as possible are channeled into the manufacture of high-quality modules. Even in a well-operated production process, a considerable amount of cells fail to pass the demanding quality tests. At first glance, that might seem a relatively negligible amount. However, given tighter margins and the energy and material expenditure involved in manufacturing cells, it is also beneficial taking 100% of the production into consideration. This is where Innotech Solar comes in.

Analysis and Optimization Instead of Re-melting

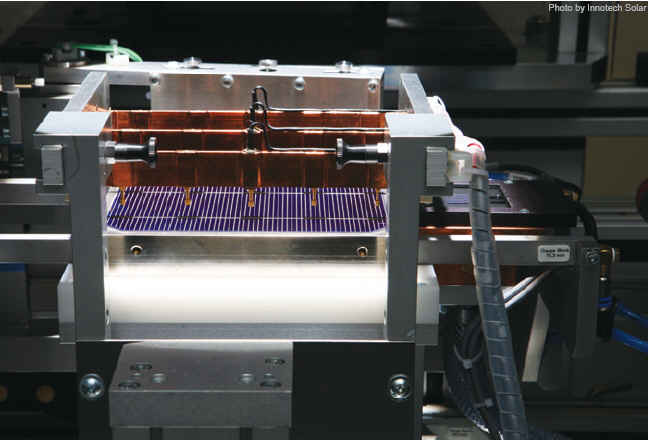

The aim of Innotech Solar is to increase the efficiency of the solar value chain. The company¡¯s philosophy is to make the best use of all solar cells. It optimizes the rejected solar cells and employs industrial processes developed by their own research teams. It tests, sorts and optimizes more cells from different manufacturers than any other cell or module provider in the world (Photo 1, Photo 2). Production is based in Norway and subsidiaries are located in Germany, China and Switzerland.

Innotech Solar buys cells with performance deficiencies and visual imperfections from various international manufacturers and subjects them to their processes. The processed cells are then utilized in Innotech Solar¡¯s solar modules. The modules have the same performance and quality as conventional high-power modules. At the same time, they are particularly environmentally friendly, since initially rejected cells regain their full performance capacity.

Impurities Cause Shunts

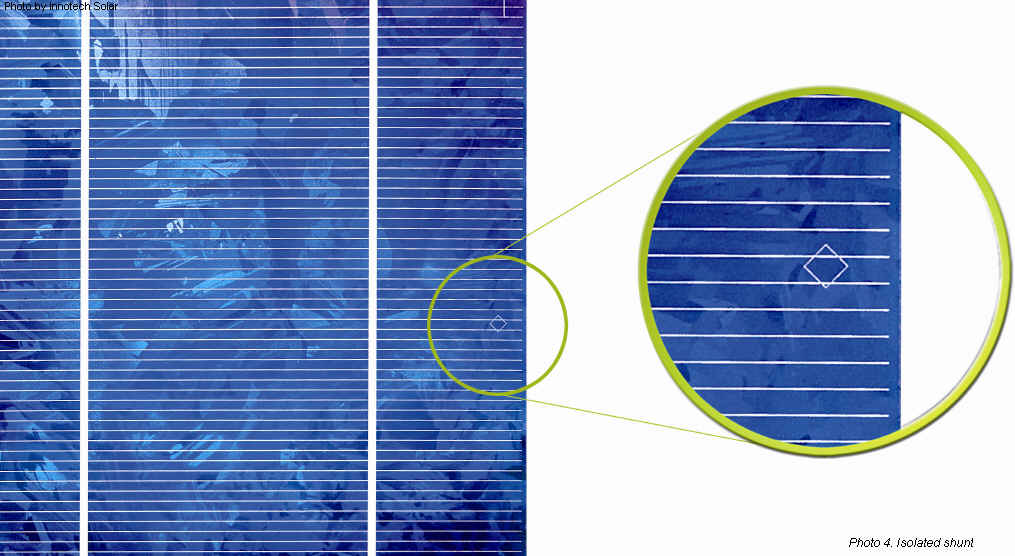

One of the origins of faults are so-called shunts. These are caused by, among other factors, the smallest impurities in the silicon used to manufacture poly- and monocrystalline solar cells. Although the impurities cannot be seen with the naked eye, solar cells with such shunts perform worse and often no longer achieve the quality required.

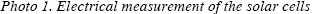

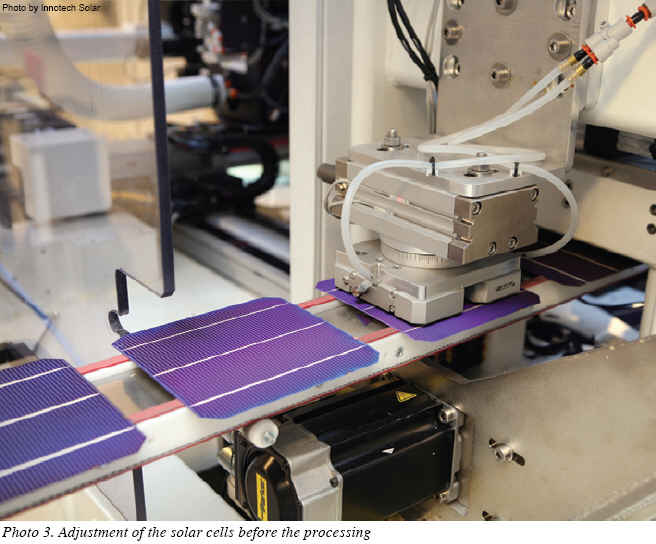

In more than two years of research work, Innotech Solar has developed an industrial process to identify shunts in cells from various manufacturers and then isolate them automatically with laser technology: this deactivates the shunts. The performance losses caused by inactive cell surfaces are so insignificant that they cannot be measured. One of the greatest challenges facing the researchers in Narvik, Norway, was to find the right laser-parameters. They finally achieved this in the summer of 2009, consequently making it possible to process a wide variety of cells in series on the production line (Photo 3).

The surface area isolated by the process is generally less than 0.05% of the overall solar cell surface area. Following optimization of the cells, it is not possible to detect any deviation in the performance compared to conventional cells (Photo 4).

Half Cell and Third Cell Modules Reduce Solar Power Costs

Until now, all cells with major impurities, which could not be handled by the main laser-process had to be sorted out, even if a considerable part of the cell was fully functional. New production steps developed by Innotech Solar have made it possible to isolate even larger impure zones: a laser cuts off the non-functional parts of the cell so that only the fully-functioning remaining halves or thirds are further used. Cells that up until recently would have been rejected can now be used for the production of high-quality modules, subsequently making cell and module production even more efficient and environmentally friendly.

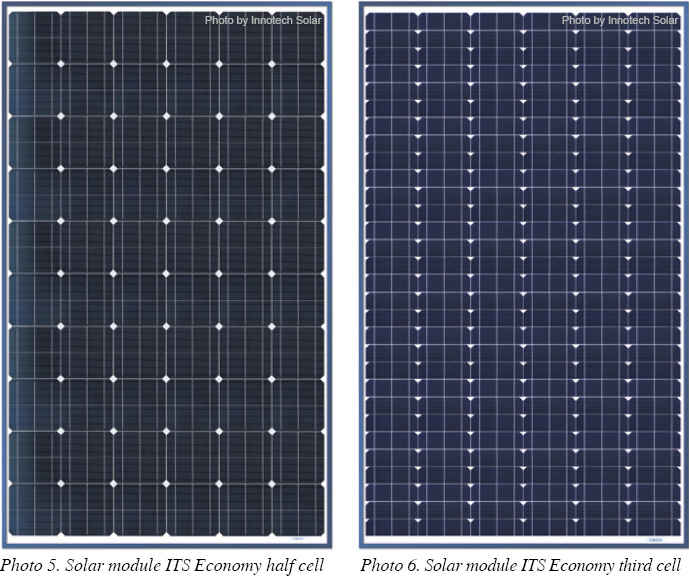

Multi-stage testing and optimization processes guarantee a high performance level comparable to that of conventional modules. The ¡®ITS Economy half cell¡¯ and ¡®ITS Economy third cell¡¯ modules are particularly suitable for large roof and ground-mounted systems and have been certified by TV Rheinland according to IEC standards. The ¡®ITS Economy half cell¡¯ and ¡®ITS Economy third cell¡¯ modules are available as 200, 210, 220 and 230 Wp modules (Photo 5, Photo 6).

Modules Produced by Quality Module Manufacturers

.jpg) ITS works with two OEM-partners for module production. As well at this production step, ITS puts the main focus on quality criteria. One produces in Germany, the other in Asia and both OEM-partners are quality leaders who enjoy an excellent reputation in the market and are certified according to ISO. ITS works with two OEM-partners for module production. As well at this production step, ITS puts the main focus on quality criteria. One produces in Germany, the other in Asia and both OEM-partners are quality leaders who enjoy an excellent reputation in the market and are certified according to ISO.

Due to a positive sorting, the customers gain additional power output: a 220 Wp module has actual flash results of 220-230 Wp, for instance. Innotech Solar modules comply with the European and U.S. standards. Their quality is tested by independent institutes such as TV and the Photovoltaik Institute Berlin (PI). During a whole series of module tests, the PI did not find any deviation from standard crystalline modules. There is a 5-year product warranty. Just as other providers, Innotech Solar guarantees a power output of 90 percent for ten years and 80% for 25 years for all its modules.

Customer Benefit

Innotech Solar modules are believed to be the most environmentally friendly crystalline modules in the market. This fact is relevant for many customers. For example, Green City Energy used Innotech Solar modules on the roof of the AUDI factory in Ingolstadt, Germany. The main reason was due to their performance, combined with their especially short energy amortization period (Photo 7).

In the initial phase, Innotech Solar introduced its solar modules in the German market. Here, projects in the multi-megawatt range were built. Consequently, the contracts have been signed as well for projects in the United States, Italy, France, Spain, Portugal, Czech Republic, Sweden, Austria, Turkey, Greece, and New Zealand. In addition, Innotech Solar has just introduced off-grid modules with power classes of 70, 80, and 90 Wp. These modules are perfectly suitable for remote applications in areas where no grid-connection is available. One of the main targets for these series of modules will be rural areas in developing countries.

By the end of the year, Innotech Solar will increase its production capacity to approximately 100 MWp and continue the already initiated internationalization processes.

Benefits for Cell Manufacturers

The cell manufacturers also benefit from working with Innotech Solar. Indeed, if they were to sell the unprocessed cells elsewhere, there is a risk that the cells end up being installed in low-quality modules, which would harm the image of the manufacturer if they reached the market. Innotech Solar, on the other hand, guarantees that unprocessed cells--that would, otherwise, perform inadequately--are not distributed in an uncontrolled manner. It is not profitable for individual manufacturers to develop their own cell optimization capacities, because the volume of cells requiring optimization is too low. An example of co-operation is the long-term strategic partnership with Q-Cells SE and Bosch. So, Q-Cells SE will, for instance, sell all of its non-prime solar cells to Innotech Solar for conversion into PV solutions worldwide under the Innotech Solar brand name.

For more information, please send your e-mails to pved@infothe.com.

¨Ï2010 www.interpv.net All rights reserved.

|