Up to 15 identical power modules in the Fronius CL create a redundant system. A well-thought-out concept for the highest stability

Master-slave Concept

The classic master-slave concept works in such a way that in a system comprising two or more inverters, one of them is nominated as the permanent master. This master is responsible for controlling the slaves and, therefore, for managing the system. It begins its work in the morning and, as soon as sunlight levels increase, switches the other slaves on as and when required. On cloudy days or in the winter, the master can work alone while the slaves remain switched off.

This mode of operation means that the master quickly clocks up far more operating hours than the slaves. Even compared with inverters that are not working in master-slave mode, a master inverter works many more hours under full load, and this, therefore, places more stress on its components. From a statistical point of view, this fact unsurprisingly means that the master is subjected to a higher probability of failure than ¡®normal¡¯ inverters and a much higher probability of failure than its slaves. This is, particularly, inconvenient, as when the master fails, the slaves will stop working as well, since, as mentioned above, the master is responsible for managing the slaves and switching them on when required.

The upshot of all this is that the probability of the master failing is comparatively high and, when it fails, the entire system will stop working. This can result in embarrassing drops in yield, especially in large PV systems.

The Basics: MIX System

The MIX system is an extension of the master-slave process that has the same advantages in terms of partial load efficiency without the disadvantages relating to operating hours and failures.

The name ¡®Master Inverter X-change (MIX)¡¯ more or less explains how the system works: one power stage set (the master) is responsible for coordination and controls the use of the other power stage sets (Fronius has extended this principle for up to 15 power stage sets). The control software assigns the role of the master to the power stage sets alternately. This work-sharing method reduces the number of operating hours of the individual power stage sets and improves yield in partial load situations.

The following describes in detail how this works: all power stage sets are essentially equal and can take on the functions of both the master and the slave, each one having its own operating hours counter. Every time the inverter is restarted (usually every morning), the control software checks which power stage set has the lowest number of operating hours and allocates it the master role (for that day). As soon as the PV output exceeds a certain value (depending on the nominal output of the inverter), the master switches on a slave. The operating hours are checked again the following morning and--depending on the number of operating hours already worked--a different power stage set becomes the master. With regard to stability, this system, therefore, sets the highest standards. After all, if the master develops a fault, a slave can take over its role and the inverter can continue to supply electricity. In other words, when a master fails, there is little or no drop in yield. If the failure occurs in the afternoon, on cloudy days or in the winter, the power stage sets that are in good working order can take on all the work so that no kWh are ¡®lost¡¯

Details of the MIX System

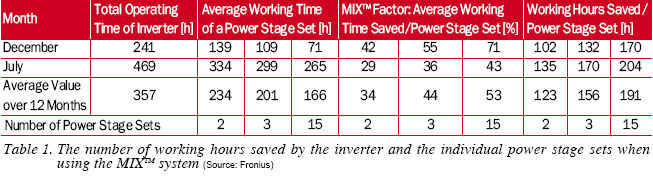

Work sharing saves time. Table 1 shows the number of working hours saved by the inverter and the individual power stage sets when using the MIX system. This example uses a Fronius IG Plus 100 with 2 power stage sets, a Fronius IG Plus 150 with 3 power stage sets and a Fronius CL 60.0 with 15 power stage sets. The first column ¡®Total operating time of inverter¡¯ shows how many hours the inverter has worked in a particular month. The second column shows the average time per power stage set for 2, 3 and 15 power stage sets.

In a typical winter month, such as December, the inverter supplied 241 hours of energy. This time is split between 2, 3 or 15 power stage sets, each of which worked a mere 139, 109 and 71 hours respectively. Due to the relatively low level of insolation in December, the sets were usually only switched on one at a time. With the Fronius CL, remember that it is always connected in blocks of three when there are more than three power stage sets.

The percentage of time that a power stage set did not need to operate is shown as the MIXTM factor (up to 70% in the case of 15 power stage sets).

In a typical summer month, such as July, the operating hours of the inverter increased to 469. On average, a power stage set worked for 334 hours (2 power stage sets), 299 hours (3 power stage sets) and 265 hours (15 power stage sets). During this month of high insolation, the MIX factor is 29% for 2 power stage sets and up to 44% for 15 power stage sets. At best, the MIXTM factor can reach 50% for 2 power stage sets, 66% for 3 power stage sets and 93% for 15 power stage sets--in situations when exactly only one power stage set is working each day and the second (and subsequent ones) are never switched on. The average percentage of operating hours saved per year is, however, around 34%-53% (2-15 power stage sets).

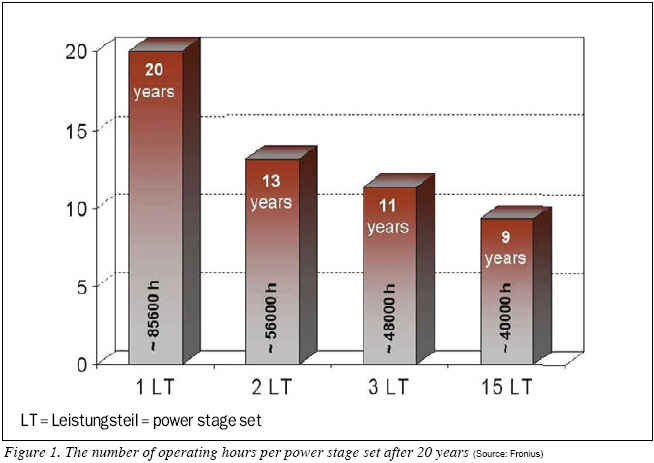

Figure 1 shows the number of operating hours per power stage set after 20 years. These amount to approx. 13 years in the case of 2 power stage sets, approx. 11 years for 3 power stage sets and approx. 9 years for 15 power stage sets.

Higher Partial Load Efficiency Generates Higher Yield

If we put the Fronius CL 60.0 with its 15 power stage sets next to an inverter with only one power stage set, the Fronius CL generates a considerably higher yield due to its higher partial load efficiency.

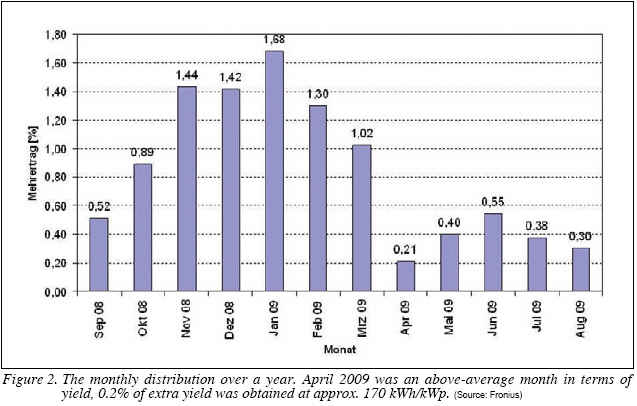

If we calculate a month¡¯s average value over a year, this extra yield is about 0.6 %. However, it can reach 1.7% at approx. 30 kWh/kWp during the winter months and as much as 8% (at approx. 0.17 kWh/ kWp) on cloudy days.

The monthly distribution over a year is shown in Figure 2. April 2009 was an above-average month in terms of yield, 0.2% of extra yield was obtained at approx. 170 kWh/kWp.

.jpg)

Advantages Compared to the Master-slave Method

Two inverters working together using the master-slave method generate the same amount of power under partial loads as an inverter using the Fronius MIX system. Nevertheless, the Fronius MIX system differs from the master-slave method in two important respects:

No Fixed Master

With the master-slave method, one inverter is the fixed master. The master, therefore, works 100% of the operating hours. The slave works around 44% in the summer, falling to approx. 14% in the winter, giving an average utilization of 29% over the year as a whole. In the Fronius MIX system, the operating hours are split evenly between the power stage sets, which means that a power stage set will only work an average of 66% of the total working hours over the year.

Protection When the System Fails

If the master in a master-slave system fails, the entire system stops, as the slave only works when the master is also working. Should a power stage set in the MIX system fail, another power stage set takes on the work. Energy losses will only occur when the insolation level is high, and even then they will be limited.

For more information, please send your e-mails to pved@infothe.com.

¨Ï2010 www.interpv.net All rights reserved.

|