Reported by Jeanny Lim (swied@infothe.com)

You have 25 years of experience in robotics systems. How do you meet the unique demands of today’s solar industry?

The three main goals of a solar manufacturer are to increase throughput, minimize breakage, and reduce scrap.

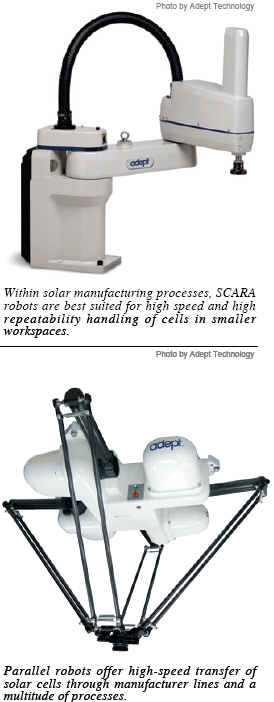

-Increase throughput: Adept offers the fastest SCARA and parallel-link robots in the world. These two kinematic models account for the majority of robotic placements within the solar cell manufacturing space.

-Minimize breakage and reduce scrap: With advanced servo algorithms, high-speed servo electronics (8 kHz servo loops), high-resolution encoders, and unique kinematics, Adept’s robots have been tested and field-proven to provide the smoothest and most gentle handling for wafers and solar cells.

-Applications expertise: Adept’s applications and systems engineers have years of specific experience in working with the leading OEM providers of photovoltaic process equipment to refine processes and product transfers to maximize line productivity.

In the solar market, where do you put your focus this year in terms of both business growth and technology development? In the solar market, where do you put your focus this year in terms of both business growth and technology development?

Business growth: Our focus is in working with leading automation solution providers and OEM process equipment manufacturers supplying to c-Si manufacturers in China, Taiwan, Korea, and India. In comparison with 2009, there has been a marked recovery in global demand for solar products, particularly from China and Taiwan. This has driven new rounds of capacity expansions and demand for automated solutions for handling solar cells. Significant new capacity is also starting to come online in Korea with major manufacturers like LG and Samsung expanding their businesses in renewable energy. We also expect significant new manufacturing activity in India as projects benefiting from the recently approved National Solar Mission are deployed.

Technology development: We have expanded our Adept QuattroTM robot product family by introducing a new model with a larger 1,600 mm diameter work envelope to meet the needs of PV equipment manufacturers for wafer and cell load and unload automation. We are seeing trends in increasing sizes and capacities in machines for anti-reflective coating and inspection and sorting of wafers and cells which require robotics with a combination of high-speeds, gentle handling, and large work envelopes.

Producing high-efficiency solar cells in a cost-effective way has always been the issue for the solar industry. How is Adept Technology tackling it?

Adept doesn’t specifically offer the products or technologies that improve the efficiency of solar cells, but we do provide the wafer and cell handling solutions that allow manufactures to produce them cost-effectively. Our robot products are not only the most gentle in the industry (reducing breakage and increasing yields), but they are also the fastest in the industry (increasing throughput and reducing cost per unit).

What’s next at Adept Technology as you strive to improve your technologies and drive solar manufacturing innovation?

-Continued investment into software for applications development and runtime environment for rapid deployment of turnkey systems. Plus an expanded user experience imitative to provide greater tools and capabilities effectively reducing programming time and improving the interface between operators and the equipment.

-Continuous improvement in controls technology with fast processing, more efficient servo and trajectory generation algorithms, more efficient robot kinematics. Adept will release the CX controller later this year which provides a higher level of performance and expanded capabilities as compared to previous generation controller while continuing to provide the smallest controller footprint in the industry.

-Continuous improvement in robot technology for smoother motions and greater control and repeatability through the refinement of platforms used to wield tooling on our popular Quattro product line.

-Lastly, our recent acquisition of the leading autonomous robotics company MobileRobots has drawn great interest from solar manufacturers and OEMs who are interested in exploring how this technology can be used for a variety of processes within the manufacturing of solar panels. The areas of interest include transferring cassettes from processing equipment in batch processes, line replenishment, intelligent handling and management of panels and logistics between the warehouse and production.

Could you tell us some of the competitive edges that differentiate you from your competitors in the solar market?

We have fastest robots in the industry (recently demonstrated our Quattro product line achieving over 300 cycles per minute), smoothest robots in the industry (advanced encoder technology for greater resolution; faster processors; advanced servo algorithms), smallest controls and robotics footprint in the industry, most knowledgeable applications and systems engineering capability for handling c-Si wafers and solar cells, and 25+ years of experience in working with Global 1000 manufacturers for high-speed, high-volume handling applications

What have you been doing to grow your presence in the international solar arena?

European PV equipment manufacturers have dominated the PV equipment market for well over 10 years, but there is a trend for PV manufactures to start sourcing from local providers to take advantage of lower equipment costs and localized service and support. In general, we are investing our resources to partner with these regional equipment manufacturers to realize the benefits of our products while we provide specific application expertise for the robotic handling of solar wafers and cells. Our focus has been on the growing Asian markets for solar wafer and cell manufacturers. For example, in Taiwan, we established a new partnership with CASTEC International Corp. (an experienced solutions provider for the semiconductor, FPD, and solar industries) to supply major Taiwan solar cell manufacturers with automated load/unload solutions incorporating Adept robots.

Please introduce your management philosophy that you have been pursuing.

Our business philosophy has been one of thought leadership and technological innovation. We invest in our people and into our research and development to where we are equipped to meet our customers and client’s needs not only today, but tomorrow. This not only entails bringing the most advanced automation to the world, it requires us to do so while delivering economic value. We manage the business recognizing that we must simultaneously address the needs of our three constituents; our customers, our employees and our investors.

What are your expectations for the development of the PV market in your country in 2010?

In the United States, the new federal and state governmental programs and investments in renewable energy and technologies are leading to a surge in green product manufacturing. Manufacturers of solar panels are opening new businesses and adding manufacturing capacity in states like California with strong economic incentives to create green jobs. While wafers and cells will continue to be imported, primarily from China, Taiwan, and Japan, we expect a continued trend towards localization of solar panel manufacturing in the countries and regions where the solar panels will ultimately be installed.

Jeanny Lim is Editor-in-Chief of InterPV. Send your comments to swied@infothe.com.

For more information, please send your e-mails to pved@infothe.com.

ⓒ2010 www.interpv.net All rights reserved.

|