By Tom Dinkel

.jpg)

.jpg) Local Control Local Control

In the industrial measurement and control world─which is where much of the monitoring technology has descended from─the goal for monitoring is either to measure a variable in order to take some action, or measure a variable for regulatory compliance. Sample rates it the industrial world tend to be rapid, often in fractions of a second or measured in seconds. PLCs (Programmable Loop Controllers) are a typical feature on production lines in either discrete or process lines, and typically utilize sensors with common control outputs such as 4-20 mA, or 0-5 VDC. The ‘progammable’ part of the equation takes in frequent samples and issues commands based upon some pre-set conrtrol algorithm to take action based upon the inputs received from the sensors.

Control Systems

In the industrial space, many PLCs can be networked together via a common communications bus to provide a process-wide control system, with supervisory control functions at some central location. In some instances, the SCADA (Supervisory Control and Data Acquisition) system provides some alarming function based upon certain set-points or control points. These systems can vary from a few points to many thousands of points─a ‘point’ being either the variable being measured, or the actual PLC being supervised, and in some instances, controlled.

Utility Metering

The utility market has been measuring the consumption of gas, electricity, and water for over 100 years, and various historical attributes remain in the utility marketplace. While industrial control systems can number into the millions of data gathering points with sub-second interval gathering of data, the utility sector has vastly lower data collection requirements. Prior to the advent of the smart grid, the ‘atomic particle’ of data for the utility was monthly data for each residential customer. The data from the homes was gathered manually, from meter readers who walked from house to house. Compared to the previously described industrial data gathering and management schema, this still sounds remarkably primitive, however, manual meter reads remain popular throughout the world to this day. Commercial and industrial customers with larger energy consumption have been using ‘Time of Use’ meters for some time, collecting a more granular set of data with a much higher resolution at 15 minute intervals. Other data such as power quality, voltage, and other operational information useful for the utility are collected as well. Still, compared to the demands of the industrial world, the utility data seems remarkable for its simplicity, and really serves one primary function ─benefiting only the utility─collect data from which an energy bill can be created.

.jpg)

The recent introduction of ‘smart meters’ and the ‘smart grid’ have created the latest challenge for the utilities─collecting and managing large data sets, and providing benefits to users from such a dataset. Utilities around the world are in the throes of demonstrating the benefits of the smartgrid to their users, with varying degrees of success. The ‘smart grid’ leaves the solar industry out of the mix completely in many roll-outs, preferring to read the ‘net-meters’ manually. There are some legacy issues at play here, and early rollouts of the smartgid failed to capture the value signs provided by the smart meter (+ or -) and as a result the billing algorithm would treat all values as additive. For example, if your home generated 400 kWh during the day and you consumed 400 kWh at night, the utility would present you with a bill for 800 kWh’s! This has been fixed in some locations, and the smartgrid once again touches the solar installation’s net meters, but in other locations─such as PG&E─the net meters are still read by hand by a physical read once per month. (Note: it is an oversimplification to say ‘by hand’ since a data gathering tool is used and the meter reader is not making physical notes on a pad as they used to, but the fact remains, there is a guy in a truck reading your net meter in a neighborhood where the home is surrounded by the ‘smart grid’.)

.jpg)

Solar Monitoring

Considering the basic functionality of the traditional utility data gathering mechanism, the solar monitoring space appears fairly modern. Borrowing technology from the industrial metering and monitoring markets, the bulk of the current offerings in the commercial solar monitoring market utilize some form of a data logger, basically a universal input with varying output capabilities. A Data Logger (DL) and a PLC differ in function in that the DL is a datagathering device, unlike the PLC which takes local action on the data it is gathering. Many of these devices, such as the ‘moxa’ unit have found their way into many of the current offerings in the solar monitoring space. The ‘moxa-box’ has inputs for many datapoints, including a universal RS485 port where Campbell Scientifics weather stations or other irradiance data is input. More advanced offerings go one step further and reach out to the combiner boxes to provide some ‘near-string’ level inputs, or actually utilize DC─current sensing or current transforming technologies to provide string-level monitoring.

At the commercial level, some inverter manufacturers have simplified the string monitoring task by providing internal register values and a communications port with published protocols which the monitoring companies have integrated into their offerings, once again utilizing the RS485 communications capabilities of the inverters.

Communications protocols are not first nature to many inverter companies, and since there was little coordination within the marketplace, and certainly none between inverter providers, the communications protocols are all slightly different. A true ‘tower of Babel’ situation, there is little reason for the inverter companies to have a strong desire to make this problem go away, despite the best efforts of initiatives such as the SunSpec Alliance. Since many inverter companies also offer some form of monitoring─some better than others─their motivation to solving the ‘lack of common communications’ problem may not be ‘top of mind’ as they plan their development priorities.

A new term has come into the solar market, however, where ‘revenue-grade’ metering has been required. The term ‘revenue-grade’ has crept out of the utility meter shop, and into the minds and plans of the regulators and program administrators of various solar monitoring programs around the world. Where revenue-grade meters have been required, an odd conflict of terms and understanding has ensued, as the solar world has been provided a glimpse into the minds and operations of the regulated utility. A revenue-grade meter, by definition, meets the accuracy and communications (a later addition) requirements as laid out in ANSI C12 and its various sub-chapters. Basically, ANSI C12 stipulates that the meter is +/- 2% accurate. And so, the solar industry has migrated to various meters with non-utility form factors (i.e., not socket-based) and with DIN rail mounting for use inside the monitoring company enclosure. The ANSI C12 standard has migrated into some (many) of the various REC trading markets in their requirements for how and when an REC is created.

An anomaly of this requirement is that many inverters have internal ‘meters’ that exceed the +/- 2% accuracy standard, however, they have not gone thru the certification process to attest to this fact. Many of the solar monitoring companies will be quick to point out that the inverters’ providing metering data is similar to a fox guarding a hen-house, although this author finds that argument wanting. The inverter company has little incentive to fudge their performance, as the penetration of the external metering is a significant portion of the market, and any such stretching of data would quickly be identified. Further, certification is regarded as a serious thing in many parts of the world, and falsification of certification documents can be criminal.

A portion of the marketplace for monitoring has seen the need for revenue grade accuracy down to the residential level, and there are some companies offering a CT-based solution feeding a ‘revenue-grade’ data logger with communications capabilities. These solutions offer no direct communications with inverters, and thus are unable to collect or process inverter performance indicators such as DC-voltage, amps, AC-voltage, VARs, or any internal errors or flags that the inverter’s control system may throw. Recent recalls exceeding 25,000 units from a leading inverter manufacturer raises the question about if those performance conditions could have been assessed remotely, and before a complete recall was warranted. One can imagine that accurate performance data might lead to some measure of remote diagnostics, or provide an early warning sign to the inverter manufacturer, if certain performance characteristics were noted.

The micro-inverter has also created an interesting transformation to the solar monitoring marketplace, as many of the micro-inverter solutions contain a monitoring solution as part of their value proposition. A utility-focused offering from Petra Solar creates an interesting model for the solar industry, as the Petra value proposition is uniquely and singularly targeted at the utility market, and offers voltage and VAR support─essentially ‘ancillary services’ in utility-speak─to utilities who might embrace their one-panel /one-inverter /one-node of communications per utility pole deployment. Key to this is a two-way communications link directly with their nodes in order to deliver the ancillary services they offer. This is a unique and fascinating value proposition, and one of which the rest of the solar industry should take note. Many in the solar industry have a somewhat guarded and slightly hostile view of the utilities, who, to their discredit, have not embraced solar or made it easy to inter-connect with ‘their’ grids. With very low market penetration, it is simpler for the utilities to provide begrudging support for the solar business, while worrying about the perceived ‘dangers’ that belie them should distributed solar become a significant portion of their generation portfolio, and scattered remotely and randomly throughout their grid, and worst of all without being under their control.

Changes may be brewing, however, as the utilities around the world begin to recognize that having an appliance such as the inverter, and a generation source available on widely distributed circuits deep into their ‘grid’, might prove to have benefits to them that they had not originally diagnosed. A look to the developments in Germany, where some circuits are loaded to 30-40% at certain times and under certain conditions with Solar Generation, and the grid operators are beginning to take notice! In the U.S.A., where solar has barely exceeded 1% of the generation portfolio in the strongest markets of CA and NJ, the grid operators and utility executives have pursued a ‘benign neglect’ strategy, at best. However, one can imagine that with inverter direct communications prevalent in the residential marketplace, the time will come that two things may occur: 1) the aggregation of those generation RECs into a trading block, and 2) the availability of the inverters to provide Ancillary Services (for which the utility will pay other providers of similar services). With two potential additional revenue streams, and clear benefits to the utility on problem circuits where voltage support is routinely needed, it may be prudent for monitoring companies to embrace a tighter relationship with both the utility, and the inverter manufacturer, in order to secure additional revenue streams for their customers.

And so the paradigm might begin to change. Most monitoring companies forgo the inverter direct communications in favor of cost savings, and revenue grade metering. In a future where inverter communications become the norm, those solutions may incur the extra costs of creating an inverter direct communications strategy, on top of their revenue-grade-metering only offerings. Others, where the recognition that inverter direct monitoring is the most cost-effective and most inverter- and utility-company beneficial, are currently forced to offer revenue-grade as an up-sell to those jurisdictions that require the standard. Clearly, it is imperative that the inverter companies pursue an effort to comply, and certify, that they are metering at an ANSI C12 compliant accuracy. This, then, will provide the best solutions for the solar market─extracting nu-neccsary costs out of the BOS (Balance of System) while attracting the most benefits for the end user─the prospect of payments for the provision of ancillary services, and the opportunity to aggregate their load into tradable T- or S-REC blocks without incurring added costs.

How Monitoring Is Done

-Data is sampled.

-Data is stored locally and/or sent to a remote location.

-The data is formatted into information that is useful to the end user.

PV Systems

Inverter Direct

-Monitor interfaces with inverter’s communication card.

-Able to gain significant amount of data about the PV system (Total power generated, Instantaneous power generated, Internal inverter errors, etc.─the list can be long depending on the inverter.)

- Installation is straight forward.

Current Transformer (CT)

-Measures power only.

-Installation can be difficult depending on size of CTs and available space in inverter/junction box.

Data Collection

-Collected at some sampling interval.

-Stored on the monitor and/or sent to a remote site.

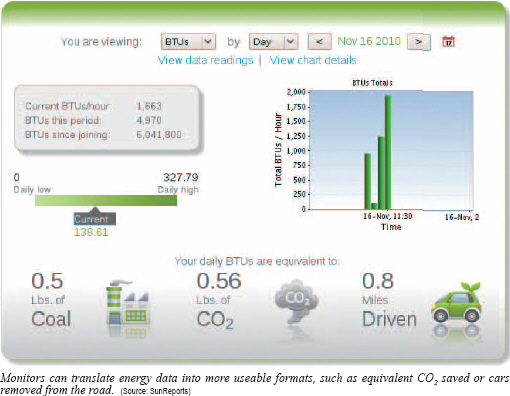

-Analyzed and calculated to determine useful information. (Energy used, Fault conditions, Energy offsets─carbon, lbs of coal, miles driven, etc.)

-Shared with customers, friends, sales leads, government/regulatory bodies.

Data Should Be Shared

-Businesses showcasing how ‘green’ they are

-Homeowners sharing with friends to promote solar/green technology

-Allows for expanded awareness and alternative energy adoption.

Tom Dinkel is the CEO of SunReports (www.sunreports.com), a provider of performance monitoring solutions for residential and small commercial solar installations. He has over 20 years of experience in the renewable energy and cleantech sector. Dinkel graduated from University of Washington with a Master’s degree in Business Administration, and holds a Bachelor of Science in Business from Oregon State University.

For more information, please send your e-mails to pved@infothe.com.

ⓒ2011 www.interpv.net All rights reserved.

|