Automatic changing system for grinding wheels

By Markus Lipp, Thomas Ommerle

The German-Swiss company, Bystronic, is entirely at home processing glass: For more than 40 years it has been recognized for providing innovative machines, systems and services in glass processing. From basic components to automated, customer-specific complete solutions, Bystronic glass offers extraordinary concepts with unsurpassed quality--and the same applies to the solar industry.

Edge Grinding of Glass Substrates

Cleanly ground edges of substrates are absolutely essential to ensure a smooth production process for solar modules. High edge quality free from cracks and shell defects is the only way to prevent glass breakage during the process. This is an important pre-condition for efficient and economical production since glass breakage is a relevant cost factor and always means a stoppage of the system. Whenever glass breakage occurs, the production systems must be run empty and cleaned. Then production has to be resumed again.

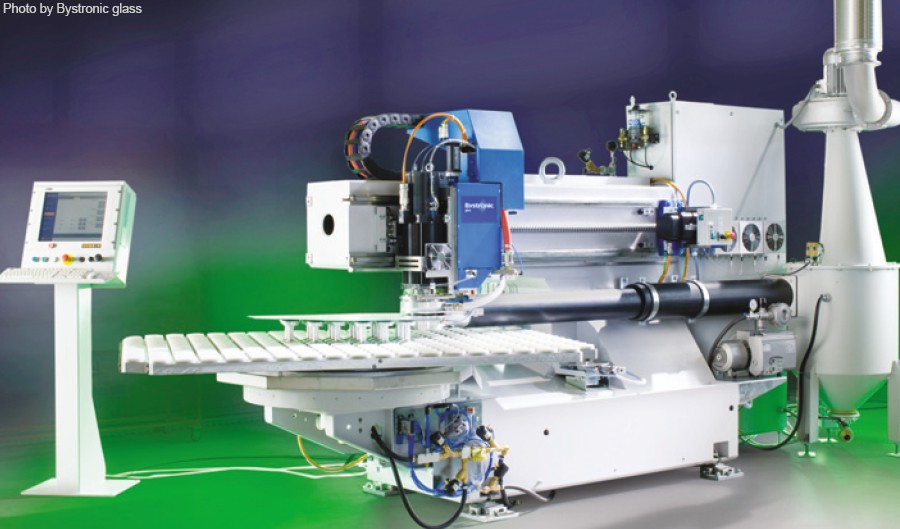

“Grinding machines from Bystronic glass stand for the highest quality in ground glass edges. For many years the company has established a strong reputation and successful track record with machines of similar design for the automotive industry,” explains Markus Lipp, Sales Manager and Project Engineer in the Swiss Bystronic glass Technology Center. Champspeed’grind makes it possible to grind edges from a minimum finished dimension of 200 mm x 200 mm to a maximum finished dimension of 2,200 mm x 2,600 mm with C grind or K grind. The yield is 99.5%.

Thanks to a mineral cast machine bed, champ’speed-series machines are completely vibration-free and can, therefore, provide the greatest precision. Substrates can be ground with extremely fine tolerances of ±0.1 mm on absolutely perpendicular sides, even if the starting substrate has large deviations in the angles. As the machines are designed as polar grinding machines with a play-free table, both edges and corners are polished in one pass, with radius or facet. All axes are equipped with maintenance-free and highly dynamic CNC direct drives. The new spindle design works in seconds with two grinding wheels arranged one over the other. “Additional time advantages are derived first from an automatic correction of the grinding wheel diameter, with changeover to another module series or substrate size taking less than five minutes, for example, as well as from the use of an automatic changing system for grinding wheels,” comments Markus Lipp in Machine Technology. Thanks to the modular layout of the series, champ’speed machines can be expanded to create large manufacturing cells with an integrated handling device and additional drilling machine.

The new champ’speedgrind by Bystronic glass

Applying Backrails Automatically

Backrails are used to fasten thin layer modules in place and to provide stability for modules with especially large surfaces. Tape or liquid adhesive is applied to modules of all sizes for this purpose. Bystronic glass Technology Center Bystronic Armatec provides semi or fully automatic systems for processing and applying backrails. They are available as a stand-alone solution or can be integrated into existing lines. “Depending on the module size, up to four rails can be placed on one module at the same time, or four rails can be placed on two modules in twin mode. This process facilitates the shortest cycle times,” explains Thomas Ommerle, Sales engineering Solar at Bystronic Armatec. Depending on the rail being processed, positioning accuracy is ±0.5 mm.

Automatic application of backrails on PV modules C grind

Bystronic glass provides customers with a system that positions backrails extremely efficiently. First, the modules are automatically positioned in pairs on the system. Preparation of the backrails runs in parallel to this process with removal of the rails from a cassette, cleaning, application of primer and adhesive and finally transfer to the assembly line. The rails are automatically positioned and placed on the back of the module. Then, the backrails are pressed into place according to the type of adhesive used. In the sorting system, modules are temporarily separated and stored vertically according to performance class. “As soon as the appropriate number for a packaging unit is reached, the system automatically moves the modules on to the next station.” Thomas Ommerle describes the range of options: “Professional packaging is available both horizontally with an automatic spacer insert and vertically in cardboard packaging with corresponding separating combs.”

Markus Lipp is Project Engineer at the Bystronic glass Technology Center Bystronic Maschinen AG (http://www.bystronic-glass.com/) in Butzberg, Switzerland. Thomas Ommerle is Sales Engineering Solar at the Bystronic glass Technology Center Bystronic Armatec in Gunzenhausen, Germany.

For more information, please send your e-mails to pved@infothe.com.

ⓒ www.interpv.net All rights reserved

|