As a worldwide leading developer and manufacturer of solar tools the German company RENNSTEIG WERKZEUGE has wide experience in the international Photovoltaik industry over many years.

Despite actual discussions, the installers awareness of high-quality and endurance has increased enormously. In the past, the users have tested different tools. Due to that, now they decide consciously for professional, reliable and durable products, says RENNSTEIG Export Manager Joachim Falk.

"The effectiveness of a PV system depends crucially on the use of reliable components such as solar modules, inverters, solar cables and photovoltaic connectors.

Of great importance is particularly the use of professional processing tools for cables and connectors. If faults are already made during the installation of a PV plant, these often manifest themselves in very short time. The result is that the calculated returns on investment are not achievable and expensive repairs follow. The main cause of defective crimp connections are in many cases assembly errors in the crimp. "states Thomas Auer, expert in the Technical Sales department at RENNSTEIG.

"In order to meet the predefined life time of 20 to 25 years for PV plants, the use and processing of solar modules, inverters and solar connectors play a key role. Extreme seasonal and weather-related environmental impacts as well as daytime radiation energies make high demands on the crimp and are critical to the system efficiency of a PV system. This also takes into account the losses due to conversion in the inverter, the length of the power line, shading and quality of the connection.

The quality of a connector generally starts with the cutting of the solar cable. A clean cut surface - i.e. no flattening of the strands - is a prerequisite for the subsequent stripping process and the subsequent introduction and positioning of the cable to crimp.

The connection between the modules is done very often with pre-assembled cables. But sometimes, cable lengths have to be adapted or cables have to be provided with new PV connectors. To cut solar cables and clean the wire without damaging, a professional installer uses a high quality cable cutter, such as the RENNSTEIG D15 cable scissor." says Mr. Auer.

“The cables used for PV plants are exposed to extreme conditions. With PV cables of professional manufacturers, you can handle temperature changes, UV rays, abrasion, etc. easily. This has the consequence that PV cable jackets contain of special features such as double insulation, strong adhesion with the wire, etc. - which causes high stripping challenges to the installer. Therefore, we have developed an patented insulation stripper for special applications which meets these high standards at all points. "says the tool expert and underlines further "Specially shaped blades cut cleanly into the cable sheath. The excellent stripping principle and ergonomics of the pliers provide an accurate stripping scope.”

“After the cutting and dismantling, the third component at the production of standard crimps at a PV-crimp connector is the use of a professional crimp tool. If the installer works with the wrong tools and isnt aware of the fact that contact, wire strands, crimp tool and setting parameters must be coordinated with each other, there are high risks.” explains Auer.

“The crimp system tool PEW 12 ensures that the plug contacts of a variety of reputable solar PV connector manufacturers will meet the highest quality. The easy change system of the crimp-system tool makes it possible to change die sets of different plug systems very quickly. No matter, whether it is a turned contact, e.g., Amphenol H4 or Multi-Contact MC3, Tyco Solarlok, Wieland Gesis etc. or a stamped contact, as for example Lumberg LC4, Multi-Contact MC4, Hosiden HSC, PV-03 SMK etc.. The parallel crimp and the optional locator application guarantee that, in any case, an optimum and reproduceable crimp occurs at the contact. This crimp corresponds to DIN Standardization EN 60352-2 or fulfils the parameters given by the contact manufacturer.”

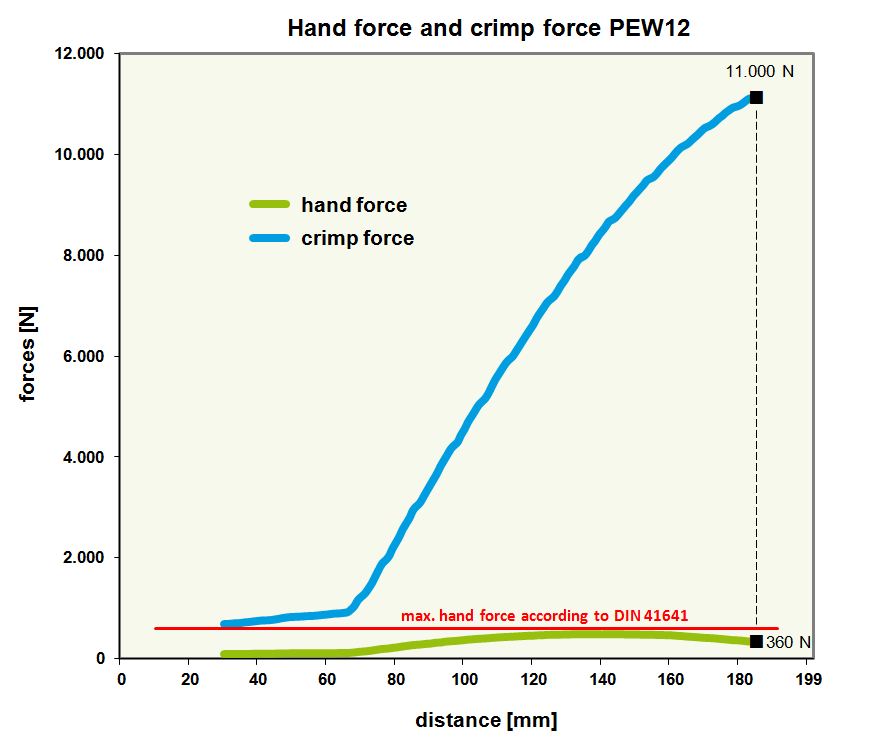

RENNSTEIG is proud of the optimally coordinated relationship between expended hand force and the crimp force achieved. In this process, the maximum allowed manual force stated in DIN 41641 was taken into account, says Auer, and emphasizes once again clearly the professionalism of the PEW 12 in the production of standardized crimps.

In this context, it seems interesting for cable manufactures, that it is possible to use the PEW 12 crimping die sets in the RENNSTEIG crimping series CM 25, too. The pure pneumatic crimping machines are ideal for the production of small and medium series and possess a 360 ° rotating work area. The machines are small, compact and very easy to use.

RENNSTEIG tools are used during the processing of many well-known connector manufacturers. Last but not least is the system pliers PEW 12 is used as a processing tool for plug certification.

Due to the fast movement in the PV market, the user must be very flexible today.

So it is quite possible that he is confronted with processed plug type at first at the installation site and has to adapt quickly to new situations.

Therefore, the RENNSTEIG PV tool kit is available both as a single hand tool as well as in various tool sets, enabling the fast adaption to the different connector systems.

The user also has the option to design a tool set according to individual needs.

RENNSTEIG is a regular participant at important international fairs. Your competent partner in South Korea is the SANG-BO Corporation.

www.sangbo.co.kr

Contact

- Germany

Rennsteig Werkzeuge GmbH

Mr. Joachim Falk

An der Koppel 1

98547 Viernau / Thüringen

j.falk@rennsteig.com ,

www.rennsteig.com, www.facebook.com/rennsteig.werkzeuge

T: +49 36847 441 -27

F: +49 36847 441 -14

- Korea

SANG-BO Corporation

Mr. Brad Choi

Shindorim-dong, Guro-Ku

152-887 Seoul

T: 2 2068 0378

F: 2 2068 0471

trade@sangbo.co.kr

|